Kev xaiv ntawm FBO molding tshuab, uas yog JN-FBO series kab rov tav parting thiab unpacking molding tshuab, muaj cov nram qab no zoo

Kev xaiv ntawm FBO molding tshuab, uas yog JN-FBO series kab rov tav parting thiab unpacking molding tshuab, muaj cov nram qab no zoo,

Kev xaiv zoo tshaj plaws - JN-FBO molding tshuab,

Txheej txheem cej luam

JN-FBO series kab rov tav parting tawm lub thawv molding tshuab integrates qhov zoo ntawm ntsug xuab zeb tua, molding thiab kab rov tav parting. Nws yog ntau thiab ntau nyiam los ntawm cov neeg ntawm kev pom hauv kev lag luam.

Cov txheej txheem ob sab ejection yuav tig lub thawv xuab zeb sab saud thiab qis qis 90 degrees, thiab ua tib zoo muab cov xuab zeb tua rau hauv txoj kab ntsug thiab cov dej bisection hom.Los ntawm sab saum toj ntawm cov xuab zeb thoob nrog lub siab, siab poob sib npaug faib rau tag nrho cov xuab zeb thoob, xuab zeb los ntawm sab saum toj mus rau hauv lub thawv xuab zeb, cov xuab zeb ntws deb yog luv, yog li nws muaj qhov zoo tshaj plaws gradient bucket kev ua tau zoo, cov xuab zeb siab. me me, yooj yim tua cov xuab zeb, thiab tsis yog qhov tsim los ntawm kev tsim thiab perforation. Cov xuab zeb deflector yog ntsia rau hauv cov xuab zeb lub qhov ncauj ntawm lub thawv xuab zeb los hloov cov kev taw qhia ntawm cov xuab zeb ntws, zoo tswj cov kev taw qhia ntawm cov xuab zeb ntws nyob rau hauv cov txheej txheem ntawm cov xuab zeb ntws, kom cov xuab zeb ntws zam lub template thiab refracts rau hauv lub pussy ntawm cov duab, uas tsis tsuas yog tiv thaiv cov duab, tab sis kuj muaj zog nyob rau hauv cov duab ntxoov ntxoo ib feem ntawm cov duab! Nws tau raug pov thawj suav tsis txheeb nyob rau hauv kev xyaum ntau lawm tias lub deflector yog cov cuab yeej zoo tshaj plaws los daws ob qhov teeb meem saum toj no zoo heev!

Sab saum toj prefilled thav duab thiab lub thawv xuab zeb sab saud, qis prefilled thav duab thiab lub thawv xuab zeb qis yog ib qho, thiab lub thickness ntawm cov xuab zeb pwm yog txiav txim siab los ntawm ntau npaum li cas cov phaj compacted nkag mus rau hauv lub thawv xuab zeb. Sand thickness xaiv cov ntawv qhia zaub mov yog teem rau ntawm tus txiv neej-tshuab kev sib txuas lus ua haujlwm vaj huam sib luag ntawm lub tshuab molding tswj txee, kom cov xuab zeb tuab tuaj yeem yooj yim teeb tsa stepless raws li cov txheej txheem casting hauv kev tsim khoom. Kev siv nyiaj txiag tshaj plaws ntawm molding xuab zeb. Txhawm rau tiv thaiv lub phaj compacted los ntawm lo rau cov xuab zeb hauv qhov chaw txias, lub tshuab cua sov yog ntsia ntawm lub phaj compacted.

Nyob rau hauv cov txheej txheem molding, txhua tus txheej txheem yuav tsum sib txawv ceev thiab siab ntawm kev ua. Peb siv lub twj tso kua mis tswj electro-hydraulic servo technology. Cov lus teb ceev ceev ntawm servo lub cev muaj zog yog siv los ua kom paub txog lub sijhawm siv roj ntawm lub sijhawm tiag tiag, thiab kev tswj xyuas meej ntawm qhov sib txawv ntawm qhov sib txawv thiab qhov ntws ntawm qhov yuav tsum tau ua hauv txhua qhov txheej txheem. Tshem tawm lub zog qhov poob ntawm kev kub siab throttling, kov yeej qhov teeb meem ntawm kev kub siab throttling tshwm sim los ntawm ib txwm "valve tswj servo" system, lub zog txuag cov nyhuv, thaum txo qhov system roj kub.

Nta

1. Raws li cov castings nrog sib txawv xuab zeb qhov siab, shooting xuab zeb qhov siab ntawm lub Upper thiab qis xuab zeb pwm tuaj yeem kho linearly stepless, uas txuag cov xuab zeb siv thiab txo cov nqi tsim khoom.

2. Siv servo lub cev muaj zog los tswj cov twj siv roj twj tso kua mis, kho lub sijhawm lub cev muaj zog kom txuag tau lub zog, txo cov roj kub thiab cua sov tshwm sim, tsis xav tau cov khoom siv dej txias.

3. Lub tshuab hydraulic yog tsim thiab tsim los ntawm cov kws tshawb fawb nkoj hauv Suav teb, ua kom ntseeg tau cov tub rog zoo.

4. Cov xuab zeb inlet ib feem yog ntsia nrog cov xuab zeb deflector, uas hloov cov kev taw qhia ntawm cov xuab zeb ntws thiab zoo tswj cov kev taw qhia ntawm cov xuab zeb ntws nyob rau hauv cov txheej txheem ntawm cov xuab zeb ntws, kom cov xuab zeb ntws zam lub template thiab refracts mus rau lub pubic ib feem ntawm cov tsos, uas tsis tsuas yog tiv thaiv cov tsos, tab sis kuj haib nyob rau hauv cov duab ntxoov ntxoo ib feem ntawm cov tsos.

5. Tshem tawm cov xuab zeb hauv qab lub thawv kom ua haujlwm nyob rau hauv qhov chaw muaj kev nyab xeeb dua, ntuj thiab tsis muaj zog.

6. Cov xuab zeb raug tua vertically los ntawm cov xuab zeb thoob rau hauv lub thawv xuab zeb los ntawm sab saum toj mus rau hauv qab, nrog cov xuab zeb filling zoo tshaj plaws.

7. Lub compacted xuab zeb pwm yog tig 90 degrees horizontally thawb tawm lub casting.

Specifications

| FORM | JN-FB03 | JN-FB04 | |

| Moulding loj | Ntev thiab dav | 500 × 600 | 600 × 700 hli |

| 508 × 610 hli | 609 × 711 | ||

| 508 × 660 hli | 650 × 750 hli | ||

| 550 × 650 hli | |||

| Qhov siab | Upper lub thawv | 130-200 Linearly adjustable | 180-250 Linearly adjustable |

| (180-250 Linearly adjustable) | (130-200 Linearly adjustable) | ||

| Hauv qab lub thawv | 130-200 Linearly adjustable | 180-200 Linearly adjustable | |

| (180-250 Linearly adjustable) | (130-250 Linearly adjustable) | ||

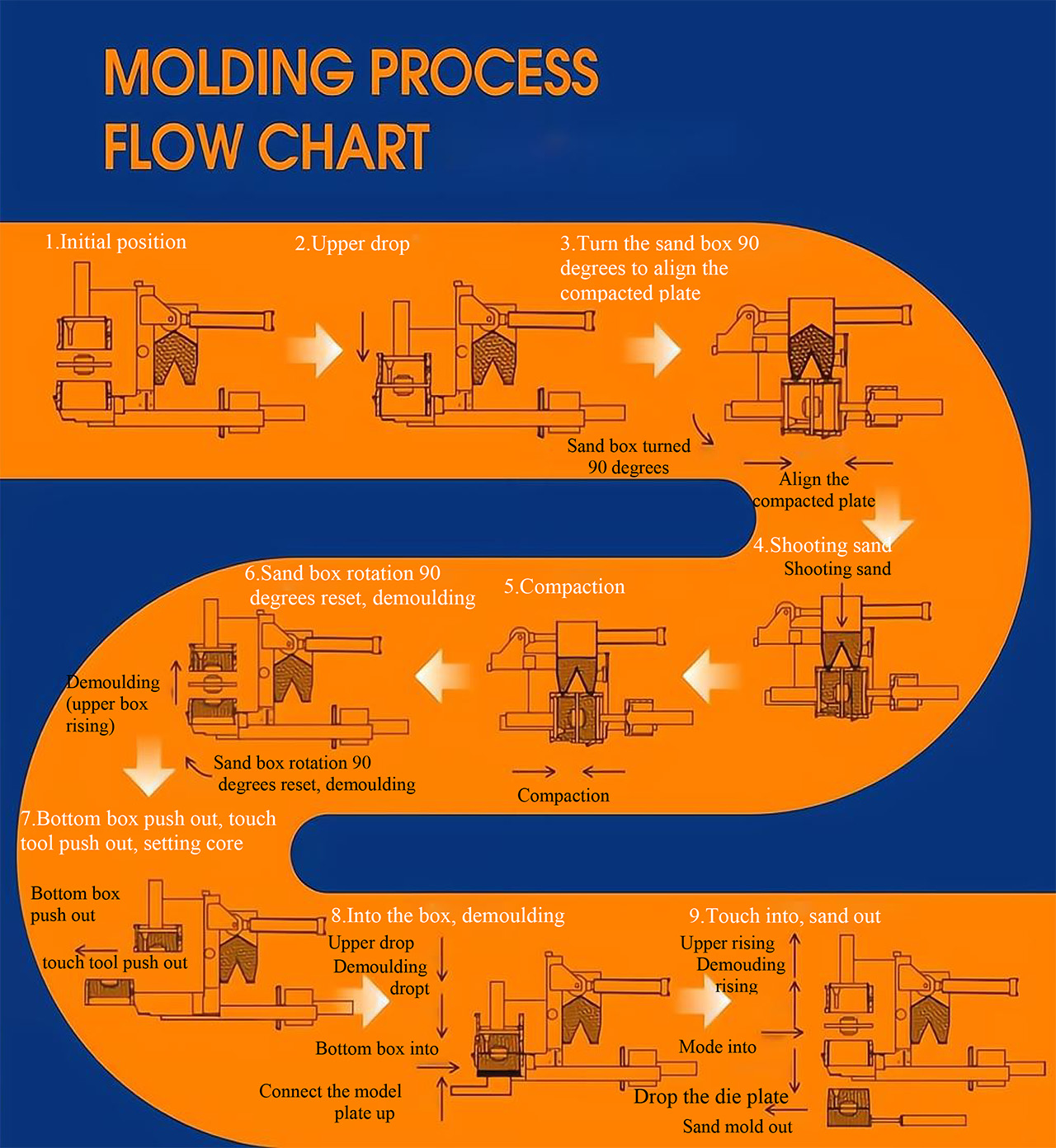

| Cov txheej txheem molding | Xuab zeb lub thawv tig 90 degree flip + sab saum toj txhaj + compaction + kab rov tav parting tawm lub thawv | ||

| Core teeb txoj kev | Lub thawv qis cia li swb tawm ntawm cov tub ntxhais qis | ||

| Moulding ceev (MAX) | 115mode / h (Lub sijhawm tseem ceeb tsis suav nrog) | 95 hom / h (Lub sijhawm tseem ceeb tsis suav nrog) | |

| Tsav tsheb hom | Compressed cua thiab servo lub cev muaj zog hydraulic tswj | ||

| Kev siv cua | 1.2Nm³ / pwm | 2.5Nm³ / pwm | |

| Ua haujlwm cua siab | 0.5-0.55Mpa (5-5.5kgf / cm³) | ||

| Lub zog tshwj xeeb | AC380V (50Hz) ua haujlwm AC220V, DC24V ncaj qha tam sim no | ||

| Cast Luj (MAX) | 117-201 Kg | 195-325 kg | |

Lub Hoobkas duab

JN-FBO Vertical Sand Shooting, Moulding thiab Kab rov tav Parting tawm ntawm lub thawv Moulding tshuab

Juneng Machinery

1. Peb yog ib qho ntawm ob peb lub tuam txhab tsim khoom hauv Suav teb uas koom nrog R & D, tsim, muag thiab kev pabcuam.

2. Cov khoom tseem ceeb ntawm peb lub tuam txhab yog txhua yam tsis siv neeg moulding tshuab, tsis siv neeg pouring tshuab thiab qauv kev sib dhos kab.

3. Peb cov cuab yeej txhawb nqa kev tsim khoom ntawm txhua yam hlau castings, li qub, nws pib qhov chaw, kav dej, thiab lwm yam. Yog tias koj xav tau, thov hu rau peb.

4. Lub tuam txhab tau teeb tsa kev pabcuam tomqab muag thiab txhim kho kev pabcuam kev pabcuam. Nrog ib tug ua tiav txheej ntawm casting machinery thiab khoom, zoo heev zoo thiab pheej yig.

Kev xaiv ntawm FBO molding tshuab, uas yog JN-FBO series kab rov tav parting thiab unpacking molding tshuab, muaj cov nram qab no zoo:

Kev xaiv ntawm FBO molding tshuab, uas yog JN-FBO series kab rov tav parting thiab unpacking molding tshuab, muaj cov nram qab no zoo:

Lub peev xwm tsim tau zoo: JN-FBO molding tshuab tuaj yeem ua tiav molding ceev ntawm 115 tus qauv / teev (tsis suav nrog lub sijhawm tseem ceeb), uas ua rau muaj txiaj ntsig zoo.

Advanced sand shooting technology: Lub tshuab molding siv ntsug xuab zeb tua thiab kab rov tav typing tshuab, uas muaj qhov zoo tshaj plaws filling kev ua tau zoo thiab tsis tshua muaj cua siab gradient, txo cov xuab zeb ntws teeb meem thaum xuab zeb tua.

Xuab zeb txhaj tshuaj GUIDE phaj: Cov ntawv qhia phaj ntawm cov xuab zeb txhaj tshuaj lub qhov ncauj hloov cov kev taw qhia ntawm cov xuab zeb ntws, tswj cov kev taw qhia ntawm cov xuab zeb zoo, tiv thaiv cov tsos thaum sau cov duab ntxoov ntxoo, thiab txhim kho qhov tseeb ntawm cov xuab zeb pwm.

Servo lub cev muaj zog tswj: servo lub cev muaj zog tswj roj twj tso kua mis tshuab, kom ua tiav lub zog txuag thiab txo cov roj kub thiab qhov tshwm sim ntawm qhov kub, tsis xav tau cov cuab yeej siv dej txias, txhim kho kev ruaj ntseg thiab txuag hluav taws xob.

Tub rog zoo hydraulic system: Lub tshuab hydraulic yog tsim thiab tsim los ntawm Suav cov kws tshawb fawb nkoj, uas ua kom muaj kev ntseeg siab thiab ua haujlwm ntev ntawm cov khoom siv.

Sand pwm thickness adjustable: raws li cov txheej txheem casting sib txawv, tuaj yeem yooj yim xaiv cov xuab zeb pwm thickness, siv cov xuab zeb zoo tshaj plaws.

Kev txuag hluav taws xob: Siv cov lus teb ceev ceev ntawm servo lub cev muaj zog kom ua tiav cov khoom siv roj tam sim, tswj qhov sib txawv ntawm lub siab thiab ntws hauv txhua txoj kev, tshem tawm lub zog poob ntawm kev kub siab throtting.

Kev tsim kho tshiab thiab kev hwm: Quanzhou Juneng Machinery Co., Ltd. tau yeej ntau lub npe qhuas, suav nrog "Tshwj xeeb thiab Tshwj Xeeb Tshiab" Kev Lag Luam Me thiab Nruab Nrab hauv Fujian Xeev, rau nws qhov kev ua tau zoo hauv kev tshawb fawb thiab kev tsim kho thiab siv cov khoom tshiab thiab thev naus laus zis los ntawm kev tsim txiaj ntawm nws lub tswv yim tshiab thiab kev paub txog kev lag luam.

Kev lees paub thoob ntiaj teb: Lub tshuab ntawm JN-FBO molding tshuab yog synchronized nrog lub ntiaj teb, thiab cov khoom tau raug xa tawm mus rau ntau lub teb chaws, kos cov txiaj ntsig ntawm kev tshawb fawb thiab kev loj hlob ntawm lub tuam txhab, nrog rau cov cim tseem ceeb ntawm kev hloov pauv thiab kev txawj ntse thiab kev txhim kho.

Cov txiaj ntsig zoo no ua rau FBO molding tshuab dhau los ua cov cuab yeej nyiam hauv kev lag luam foundry, uas tsis yog tsuas yog txhim kho kev tsim khoom thiab cov khoom zoo, tab sis kuj them nyiaj rau kev txuag hluav taws xob thiab kev tiv thaiv ib puag ncig.