OEM Hoobkas rau Static Pressure Kab rov tav Tsis Siv Neeg Ntsuab Sand Molding Ntau Lawm Kab, Foundry Machinery Manufacture

Raws li tus neeg muab kev pabcuam zoo, ntau yam khoom siv sab saum toj, cov nqi sib tw thiab kev xa khoom zoo, peb txaus siab rau cov xwm txheej zoo ntawm peb cov kev cia siab. Peb yog ib lub tuam txhab muaj zog nrog kev lag luam dav rau OEM Hoobkas rau Static Pressure Horizontal Automatic Green Sand Molding Production Line, Foundry Machinery Manufacture, Peb tuaj yeem muab koj los ntawm qhov deb tshaj plaws ntawm tus nqi txhoj puab heev thiab zoo, vim tias peb tau ua ntau tus kws tshaj lij ntxiv! Yog li thov tsis txhob yig hu rau peb.

Raws li tus neeg muab kev pabcuam zoo, ntau yam khoom siv sab saum toj, cov nqi sib tw thiab kev xa khoom zoo, peb txaus siab rau cov xwm txheej zoo ntawm peb cov kev cia siab. Peb yog ib lub tuam txhab muaj zog nrog kev lag luam dav rauTuam Tshoj Flask thiab Moulding Box, Txhawm rau ua kom cov neeg paub ntau dua peb cov khoom thiab ua kom peb lub lag luam loj, peb tau mob siab rau kev tsim kho tshiab thiab kev txhim kho, nrog rau kev hloov khoom siv. Qhov kawg tab sis tsis yog qhov tsawg tshaj plaws, peb kuj tau them nyiaj ntau dua rau kev cob qhia peb cov neeg ua haujlwm tswj hwm, cov kws tshaj lij thiab cov neeg ua haujlwm hauv txoj kev npaj.

Nta

1. du thiab txhim khu kev qha hydraulic tsav ua haujlwm

2. Kev thov ua haujlwm tsawg (ob tus neeg ua haujlwm tuaj yeem ua haujlwm ntawm cov kab sib dhos)

3. Compact assembly line model tsheb thauj mus los occupies tsawg qhov chaw tshaj lwm yam systems

4. Qhov kev teeb tsa ntawm cov txheej txheem pouring thiab cov dej ntws inoculation tuaj yeem ua tau raws li qhov xav tau sib txawv

5.Pouring lub tsho thiab pwm hnyav los xyuas kom meej cov khoom zoo ntawm cov xuab zeb tiav

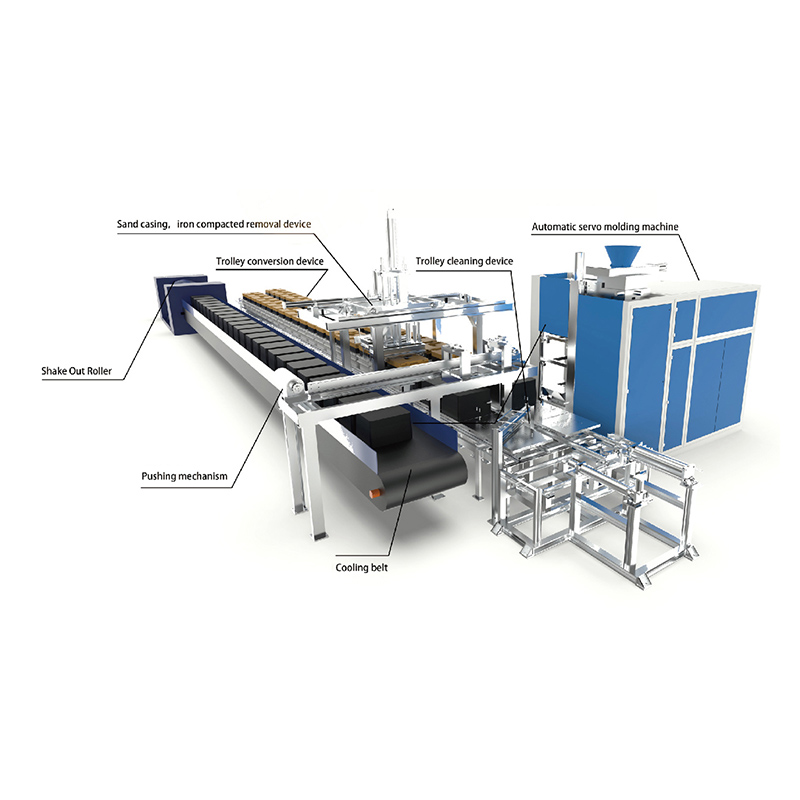

Pwm thiab Pouring

1.Un-poured pwm yuav muab cia rau ntawm lub trolley ntawm txoj kab conveyor

2.Qhov kev ncua sij hawm casting tsis cuam tshuam rau kev ua haujlwm ntawm lub tshuab molding

3.Raws li tus neeg siv yuav tsum tau nce lossis txo qhov ntev ntawm txoj siv conveyor

4. Tsis siv neeg trolley thawb yooj yim nruam molding

5.Qhov kev xaiv ntxiv ntawm lub tsho nchuav thiab pwm qhov hnyav txhim kho qhov zoo ntawm cov pwm pwm

6.Pouring tuaj yeem txav mus rau pem hauv ntej nrog cov pwm thiab muab tso rau ntawm so kom ntseeg tau tias lub ncuav ntawm tag nrho cov pwm

Lub Hoobkas duab

Tsis Siv Neeg Pouring Tshuab

Moulding Kab

Servo Sab saum toj thiab hauv qab Shooting Sand Moulding Tshuab

Juneng Machinery

1. Peb yog ib qho ntawm ob peb lub tuam txhab tsim khoom hauv Suav teb uas koom nrog R & D, tsim, muag thiab kev pabcuam.

2. Cov khoom tseem ceeb ntawm peb lub tuam txhab yog txhua yam tsis siv neeg moulding tshuab, tsis siv neeg pouring tshuab thiab qauv kev sib dhos kab.

3. Peb cov cuab yeej txhawb nqa kev tsim khoom ntawm txhua yam hlau castings, li qub, nws pib qhov chaw, kav dej, thiab lwm yam. Yog tias koj xav tau, thov hu rau peb.

4. Lub tuam txhab tau teeb tsa kev pabcuam tomqab muag thiab txhim kho kev pabcuam kev pabcuam. Nrog ib tug ua tiav txheej ntawm casting machinery thiab khoom, zoo heev zoo thiab pheej yig.

Raws li tus neeg muab kev pabcuam zoo, ntau yam khoom siv sab saum toj, cov nqi sib tw thiab kev xa khoom zoo, peb txaus siab rau cov xwm txheej zoo ntawm peb cov kev cia siab. Peb yog ib lub tuam txhab muaj zog nrog kev lag luam dav rau OEM Hoobkas rau Static Pressure Horizontal Automatic Green Sand Molding Production Line, Foundry Machinery Manufacture, Peb tuaj yeem muab koj los ntawm qhov deb tshaj plaws ntawm tus nqi txhoj puab heev thiab zoo, vim tias peb tau ua ntau tus kws tshaj lij ntxiv! Yog li thov tsis txhob yig hu rau peb.

Raws li tus neeg muab kev pabcuam zoo, ntau yam khoom siv sab saum toj, cov nqi sib tw thiab kev xa khoom zoo, peb txaus siab rau cov xwm txheej zoo ntawm peb cov kev cia siab. Peb yog ib lub tuam txhab muaj zog nrog kev lag luam dav rau OEM Hoobkas rau Static Pressure Horizontal Automatic Green Sand Molding Production Line, Foundry Machinery Manufacture, Peb tuaj yeem muab koj los ntawm qhov deb tshaj plaws ntawm tus nqi txhoj puab heev thiab zoo, vim tias peb tau ua ntau tus kws tshaj lij ntxiv! Yog li thov tsis txhob yig hu rau peb.

OEM Hoobkas rauTuam Tshoj Flask thiab Moulding Box, Txhawm rau ua kom cov neeg paub ntau dua peb cov khoom thiab ua kom peb lub lag luam loj, peb tau mob siab rau kev tsim kho tshiab thiab kev txhim kho, nrog rau kev hloov khoom siv. Qhov kawg tab sis tsis yog qhov tsawg tshaj plaws, peb kuj tau them nyiaj ntau dua rau kev cob qhia peb cov neeg ua haujlwm tswj hwm, cov kws tshaj lij thiab cov neeg ua haujlwm hauv txoj kev npaj.