Tus nqi pheej yig Tus nqi pheej yig Tsis siv neeg Kab rov tav ntsuab Sand Molding Kab, Flaskless Moulding Tshuab

Peb cov khoom lag luam feem ntau txheeb xyuas thiab ntseeg tau los ntawm cov neeg siv khoom kawg thiab yuav ntsib kev hloov pauv nyiaj txiag thiab kev sib raug zoo rau tus nqi pheej yig Tus nqi pheej yig Tsis siv neeg Kab rov tav ntsuab Sand Moulding Kab, Flaskless Moulding Tshuab , Txhua yam kev xav tau los ntawm koj yuav tau them nrog peb cov ntawv ceeb toom zoo tshaj plaws!

Peb cov khoom lag luam feem ntau raug txheeb xyuas thiab tso siab tau los ntawm cov neeg siv khoom kawg thiab yuav ua tau raws li kev hloov pauv nyiaj txiag thiab kev xav tau rau tib neeg.Tuam Tshoj Automatic Sand Moulding Tshuab thiab Sand Moulding Tshuab, Yog li peb tseem ua haujlwm tsis tu ncua. peb, tsom ntsoov rau kev ua tau zoo, thiab paub txog qhov tseem ceeb ntawm kev tiv thaiv ib puag ncig, feem ntau ntawm cov khoom lag luam tsis muaj kuab lom, cov khoom lag luam zoo ib puag ncig thiab kev daws teeb meem, rov siv dua ntawm kev daws teeb meem. Peb tau hloov kho peb cov catalog, uas qhia peb lub koom haum. n nthuav dav thiab npog cov khoom tseem ceeb uas peb xa tuaj rau tam sim no, Koj tuaj yeem tuaj xyuas peb lub vev xaib, uas suav nrog peb cov khoom lag luam tsis ntev los no. Peb tos ntsoov rau reactivating peb lub tuam txhab kev twb kev txuas.

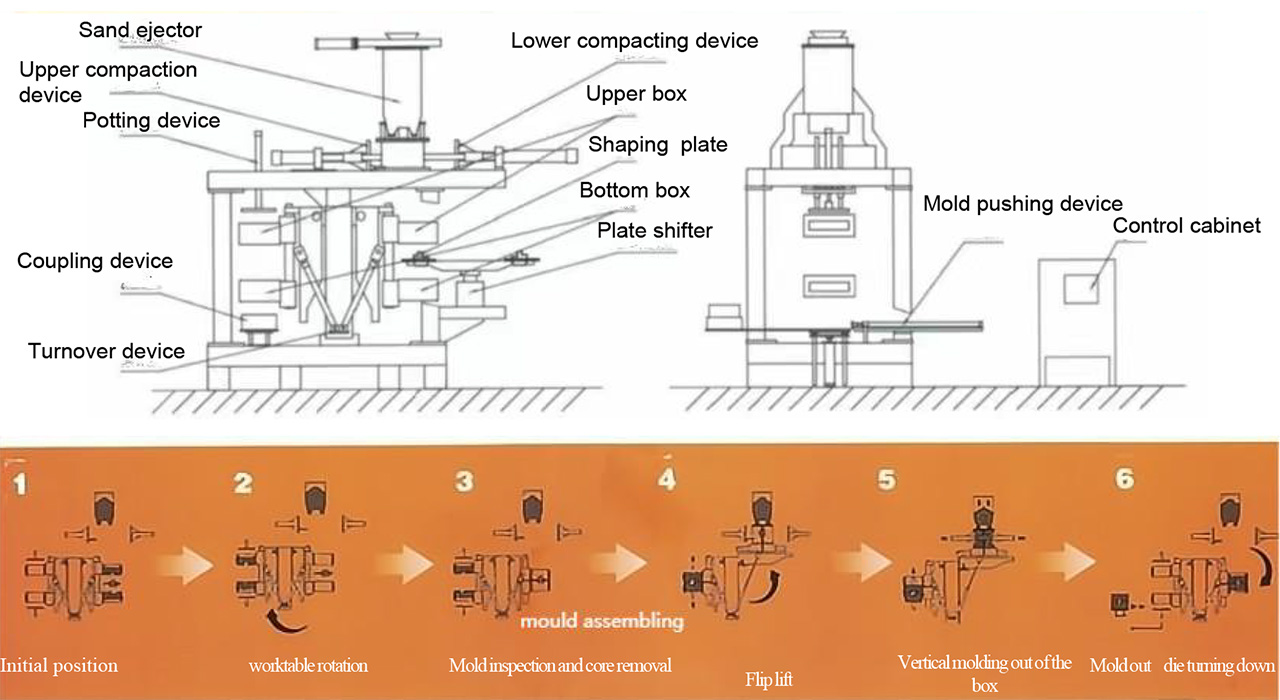

Nta

Pwm thiab Pouring

| Qhov project | 5161 ib | 5565 ib | ib 6070 |

| Pwm Dimentions (mm) | 508 × 610 hli | 550 × 650 hli | 600 × 700 hli |

| Mould qhov siab (mm) | 130-200 Nws | 130-200 Nws | 180-250 : kuv |

| Moulding ceev (ses) | 18 | 18 | 20 |

| Teem lub sijhawm tseem ceeb | 9 | 9 | 9 |

| Roj siab installation (kw) | 30 | 37 | 55 |

| Kev siv cua (Nm3 / voj voog) | 0.8 ua | 0.9 | 1.8 |

| Cov xuab zeb xav tau (T / Hr) | 35-38 : kuv | 40-50 | 45-60 : kuv |

Nta

1. Ob chav chaw nres tsheb molding thiab core tib lub sijhawm, txhim kho cov xuab zeb pwm tso zis voj voog tus nqi.

2. Cheebtsam yog tsim los ntawm imported OMRON, SRC, roj kev tshawb fawb thiab lwm yam high precision Cheebtsam, tuaj yeem txhim kho kev ua haujlwm zoo, txo qhov tshwm sim ntawm qhov tsis raug.

3. Raws li qhov yuav tsum tau muaj ntawm cov xuab zeb pwm thickness, lub sab sauv thiab qis compaction nrug yuav linearly kho.

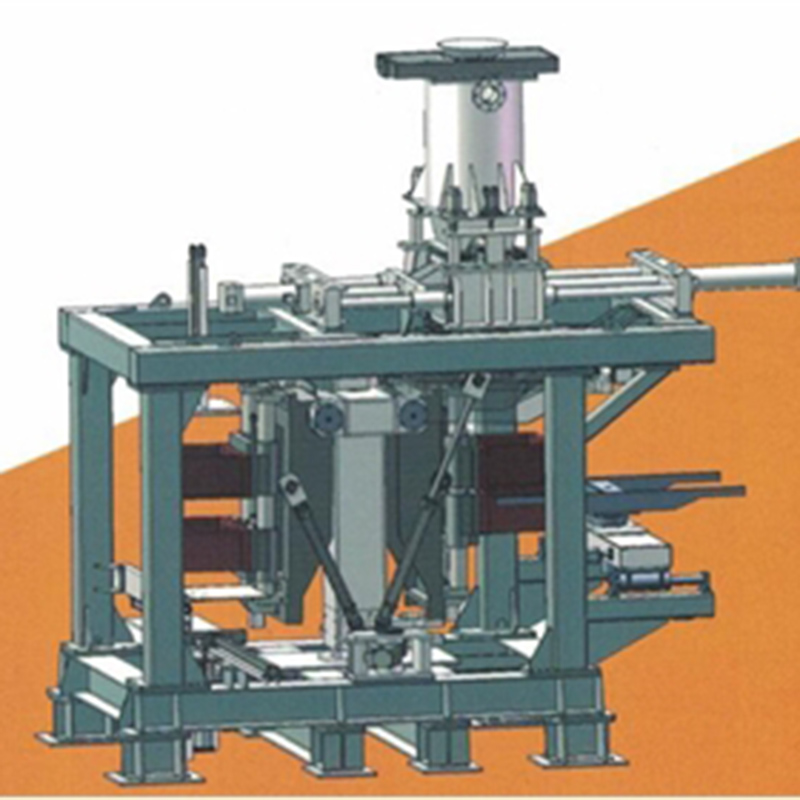

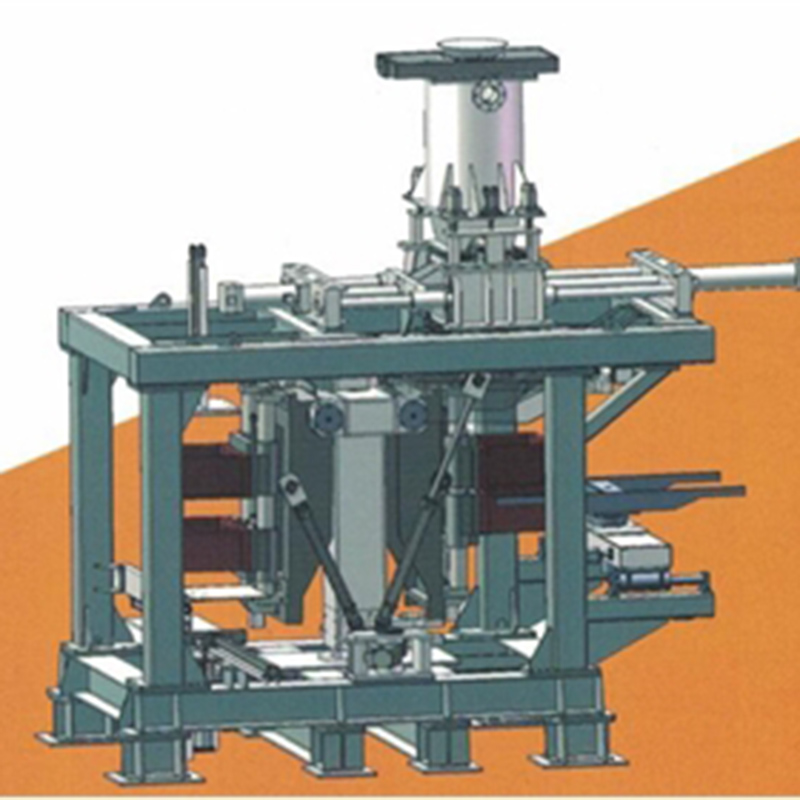

Lub Hoobkas duab

JN-FBO Vertical Sand Shooting, Moulding thiab Kab rov tav Parting tawm ntawm lub thawv Moulding tshuab

Juneng Machinery

1. Peb yog ib qho ntawm ob peb lub tuam txhab tsim khoom hauv Suav teb uas koom nrog R & D, tsim, muag thiab kev pabcuam.

2. Cov khoom tseem ceeb ntawm peb lub tuam txhab yog txhua yam tsis siv neeg moulding tshuab, tsis siv neeg pouring tshuab thiab qauv kev sib dhos kab.

3. Peb cov cuab yeej txhawb nqa kev tsim khoom ntawm txhua yam hlau castings, li qub, nws pib qhov chaw, kav dej, thiab lwm yam. Yog tias koj xav tau, thov hu rau peb.

4. Lub tuam txhab tau teeb tsa kev pabcuam tomqab muag thiab txhim kho kev pabcuam kev pabcuam. Nrog ib tug ua tiav txheej ntawm casting machinery thiab khoom, zoo heev zoo thiab pheej yig.

Peb cov khoom lag luam feem ntau txheeb xyuas thiab ntseeg tau los ntawm cov neeg siv khoom kawg thiab yuav ntsib kev hloov pauv nyiaj txiag thiab kev sib raug zoo rau tus nqi pheej yig Tus nqi pheej yig Tsis siv neeg Kab rov tav ntsuab Sand Moulding Kab, Flaskless Moulding Tshuab , Txhua yam kev xav tau los ntawm koj yuav tau them nrog peb cov ntawv ceeb toom zoo tshaj plaws!

Peb cov khoom lag luam feem ntau txheeb xyuas thiab ntseeg tau los ntawm cov neeg siv khoom kawg thiab yuav ntsib kev hloov pauv nyiaj txiag thiab kev sib raug zoo rau tus nqi pheej yig Tus nqi pheej yig Tsis siv neeg Kab rov tav ntsuab Sand Moulding Kab, Flaskless Moulding Tshuab , Txhua yam kev xav tau los ntawm koj yuav tau them nrog peb cov ntawv ceeb toom zoo tshaj plaws!

Tus nqi pheej yigTuam Tshoj Automatic Sand Moulding Tshuab thiab Sand Moulding Tshuab, Yog li peb tseem ua haujlwm tsis tu ncua. peb, tsom ntsoov rau kev ua tau zoo, thiab paub txog qhov tseem ceeb ntawm kev tiv thaiv ib puag ncig, feem ntau ntawm cov khoom lag luam tsis muaj kuab lom, cov khoom lag luam zoo ib puag ncig thiab kev daws teeb meem, rov siv dua ntawm kev daws teeb meem. Peb tau hloov kho peb cov catalog, uas qhia peb lub koom haum. n nthuav dav thiab npog cov khoom tseem ceeb uas peb xa tuaj rau tam sim no, Koj tuaj yeem tuaj xyuas peb lub vev xaib, uas suav nrog peb cov khoom lag luam tsis ntev los no. Peb tos ntsoov rau reactivating peb lub tuam txhab kev twb kev txuas.