qhov zoo thiab kev siv ntawm zawv zawg tawm tshuab molding

qhov zoo thiab kev siv ntawm zawv zawg tawm tshuab molding,

tsis siv neeg zawv zawg tawm molding tshuab,

Nta

Pwm thiab Pouring

| Cov qauv | JH3545 | JH4555 | JH5565 | JH6575 | wb 7585 |

| Xuab zeb hom (ntev) | (300-380) | (400-480) | (500-580) | (600-680) | (700-780) |

| Loj (dav) | (400-480) | (500-580) | (600-680) | (700-780) | (800-880) |

| Sand Size Qhov siab (ntev) | sab saum toj thiab hauv qab 180-300 | ||||

| Txoj kev Molding | Pneumatic xuab zeb tshuab + Extrusion | ||||

| Moulding ceev (tsis suav nrog lub sijhawm teeb tsa tseem ceeb) | 26 S/mode | 26 S/mode | 30 S / hom | 30 S / hom | 35 S / hom |

| Kev siv cua | 0,5m3 ua | 0,5m3 ua | 0,5m3 ua | 0,6m3 ua | 0,7m3 ua |

| Xuab zeb av noo | 2.5-3.5% | ||||

| Fais fab mov | AC380V lossis AC220V | ||||

| Hwj chim | 18.5 kwm | 18.5 kwm | 22 kwv | 22 kwv | 30 kwv |

| System Cua Siab | 0.6mpa ua | ||||

| Hydraulic System Siab | 16mpa ua | ||||

Nta

1. zawv zawg tawm ntawm lub thawv qis kom tso cov xuab zeb core yog yooj yim dua, yooj yim thiab tuaj yeem ua kom muaj kev nyab xeeb ntawm tus neeg teb xov tooj.

2. Cov kev xav tau sib txawv ntawm qhov yuav tsum tau ua kom yooj yim kho qhov ntsuas qhov ntsuas qhov ntsuas, kom ntseeg tau qhov zoo ntawm cov casting.

3. Raws li tus neeg yuav tsum tau muaj rau tus kheej customization ntawm molding sandbox.

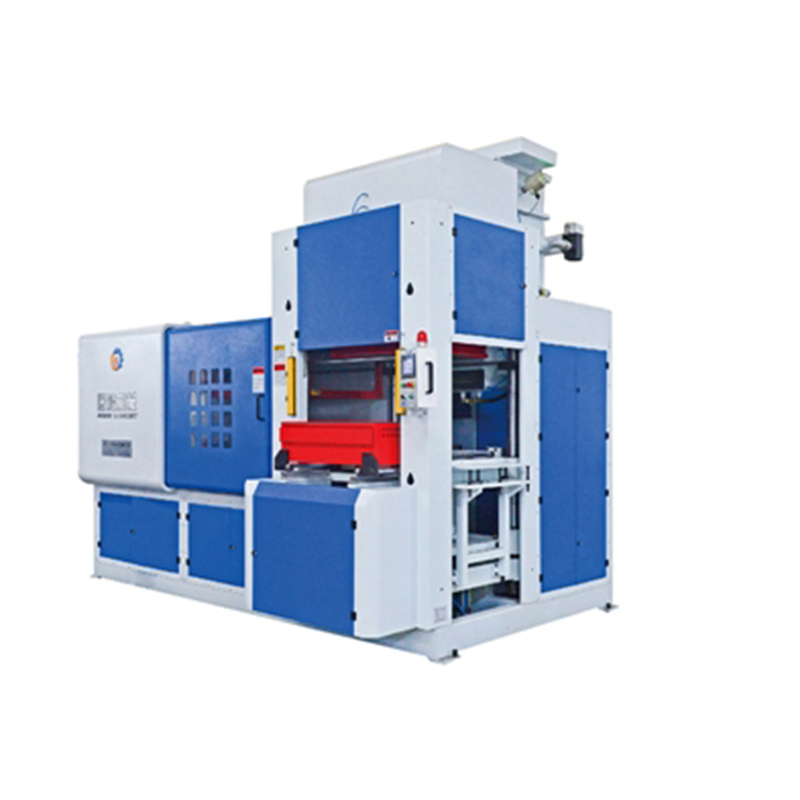

Lub Hoobkas duab

Tsis Siv Neeg Pouring Tshuab

JN-FBO Vertical Sand Shooting, Moulding thiab Kab rov tav Parting tawm ntawm lub thawv Moulding tshuab

Moulding Kab

Servo Sab saum toj thiab hauv qab Shooting Sand Moulding Tshuab

Juneng Machinery

1. Peb yog ib qho ntawm ob peb lub tuam txhab tsim khoom hauv Suav teb uas koom nrog R & D, tsim, muag thiab kev pabcuam.

2. Cov khoom tseem ceeb ntawm peb lub tuam txhab yog txhua yam tsis siv neeg moulding tshuab, tsis siv neeg pouring tshuab thiab qauv kev sib dhos kab.

3. Peb cov cuab yeej txhawb nqa kev tsim khoom ntawm txhua yam hlau castings, li qub, nws pib qhov chaw, kav dej, thiab lwm yam. Yog tias koj xav tau, thov hu rau peb.

4. Lub tuam txhab tau teeb tsa kev pabcuam tomqab muag thiab txhim kho kev pabcuam kev pabcuam. Nrog ib tug ua tiav txheej ntawm casting machinery thiab khoom, zoo heev zoo thiab pheej yig.

Lub tshuab swb-tawm molding yog cov cuab yeej siv dav hauv kev lag luam casting, uas muaj cov hauv qab no zoo thiab kev siv:

!. High precision: Lub tshuab swb-tawm moulding tshuab txais kev tswj hwm qib siab thiab precision actuator, uas tuaj yeem paub qhov siab precision pwm qhib thiab kaw qhov kev txiav txim thiab casting molding.

2. Kev ua haujlwm siab: Cov khoom siv tau qhib thiab kaw nrawm thiab lub sijhawm luv luv, uas tuaj yeem txhim kho kev tsim khoom thiab txo cov nqi tsim khoom.

3. High degree ntawm automation: lub swb-tawm molding tshuab tuaj yeem ua tiav kev ua haujlwm tsis siv neeg los ntawm kev tswj hwm kev tswj hwm, txo qhov kev cia siab ntawm kev tuav haujlwm thiab kev txhim kho automation ntawm cov kab ntau lawm.

4. Saj zawg zog thiab muaj ntau haiv neeg: lub tshuab yog tsim rau ntau yam ntawm cov txheej txheem casting, tuaj yeem hloov kho thiab hloov pauv raws li qhov xav tau ntawm cov khoom sib txawv.

5. Kev ruaj ntseg siab: Lub tshuab swb-tawm molding txais kev tsim qauv ruaj khov thiab kev tswj xyuas kev ruaj ntseg kom ntseeg tau tias kev ruaj ntseg thiab kev cia siab ntev ntawm cov txheej txheem ntau lawm.

Nyob rau hauv cov ntsiab lus, lub slide-out molding tshuab muaj qhov zoo ntawm high precision, high efficiency, siab automation, yooj thiab ntau haiv neeg, siab stability, thiab muaj ntau yam kev siv nyob rau hauv ntau yam industries nyob rau hauv lub tshav pob ntawm casting. Yog tias koj muaj lus nug ntxiv lossis xav tau cov ntaub ntawv ntxiv txog lub tshuab swb-tawm molding, thov koj xav tiv tauj kuv. Ua tsaug!